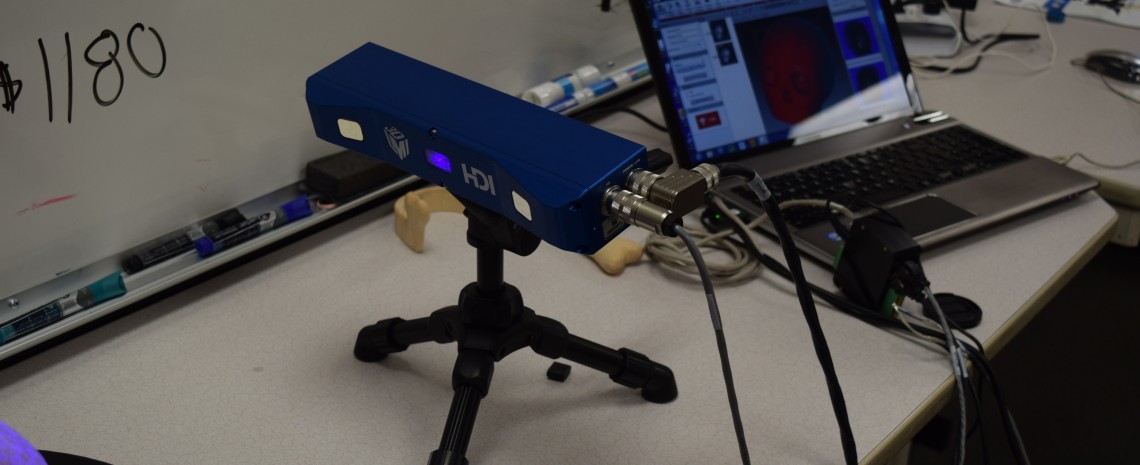

With some new research equipment arriving at the MLab over the holiday break, we’ve been pretty busy setting up and learning how to use some impressive tools. The first machine to see some use in the lab was the HDI 120 3D Scanner, made by LMI Technologies. This scanner uses blue-LED, structured-light technology to scan objects at an incredibly high resolution (up to 60 microns). It can generate digital objects with millions of polygons.

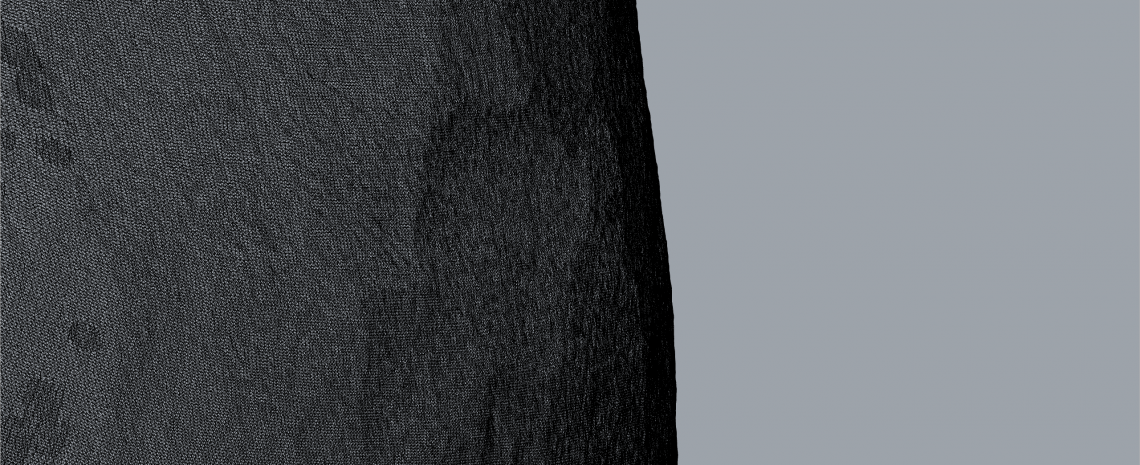

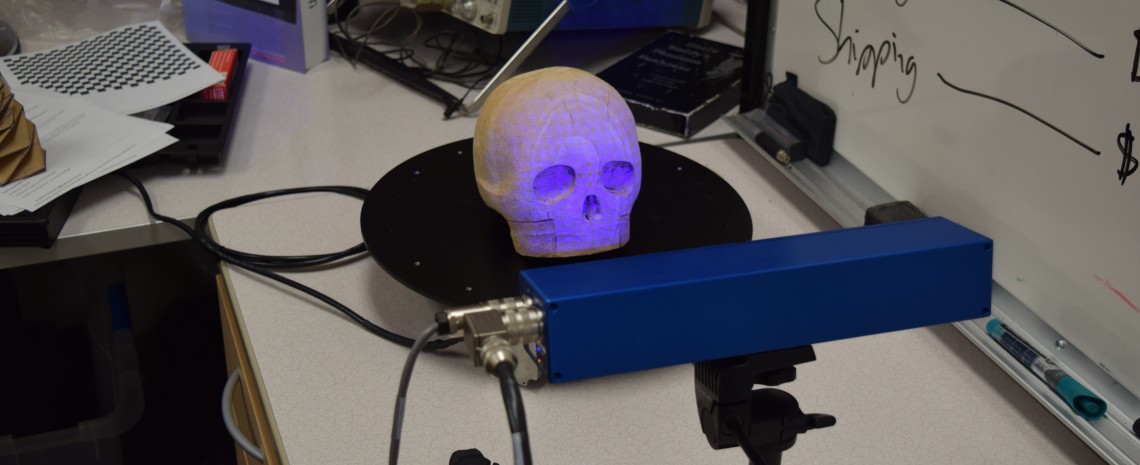

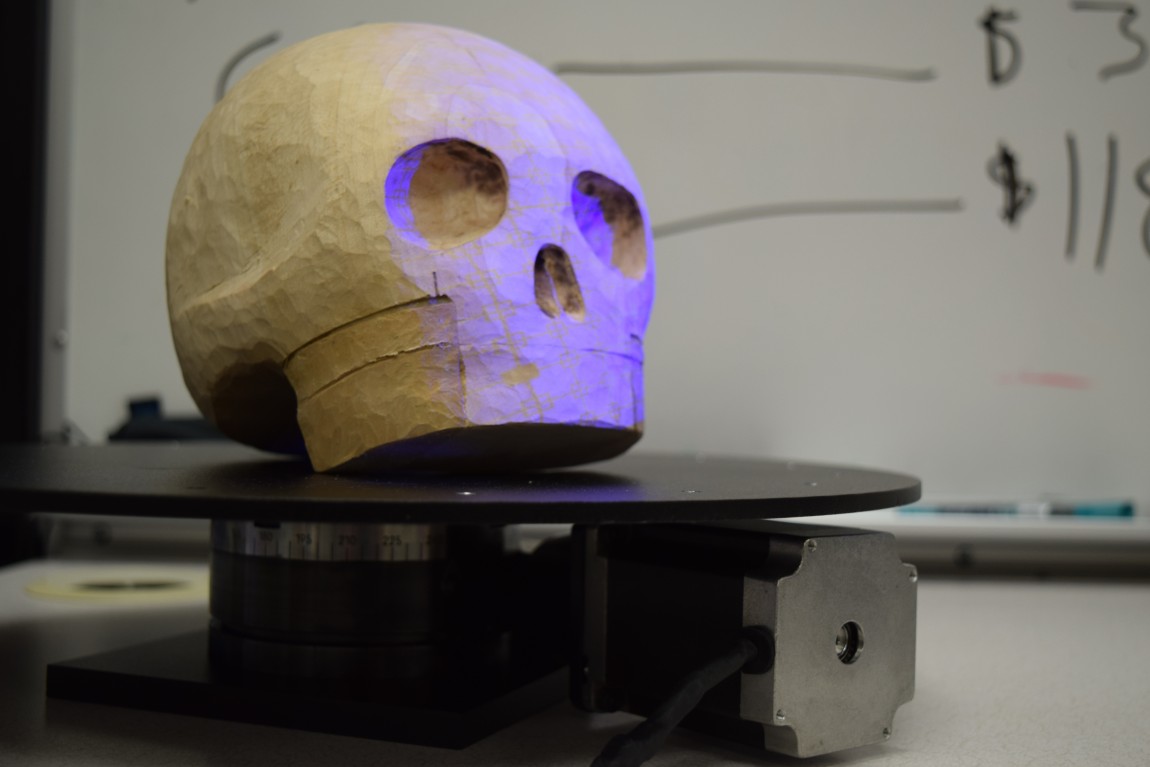

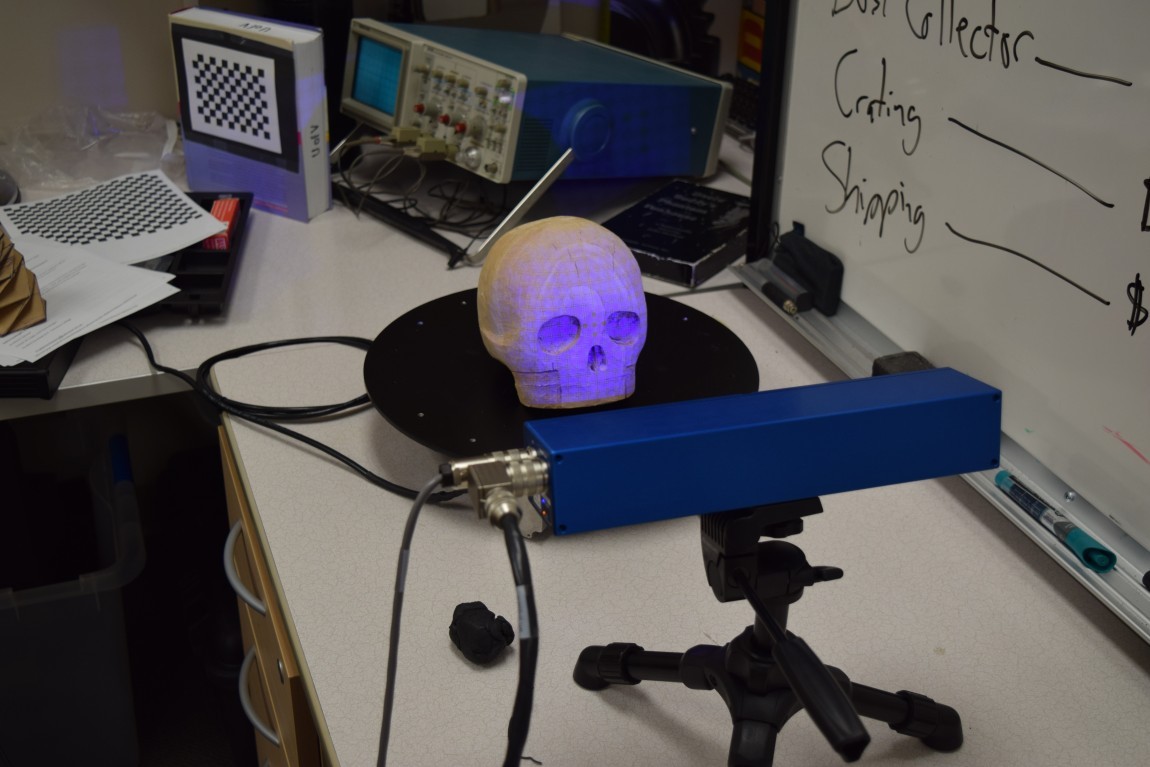

The skull model for the Trouvé pin, carved by Nicole Clouston, resting on the servo-driven turntable. The HDI 120 3D scanner uses structured-light, blue-LED technology to take high resolution images of the object as the turntable spins.

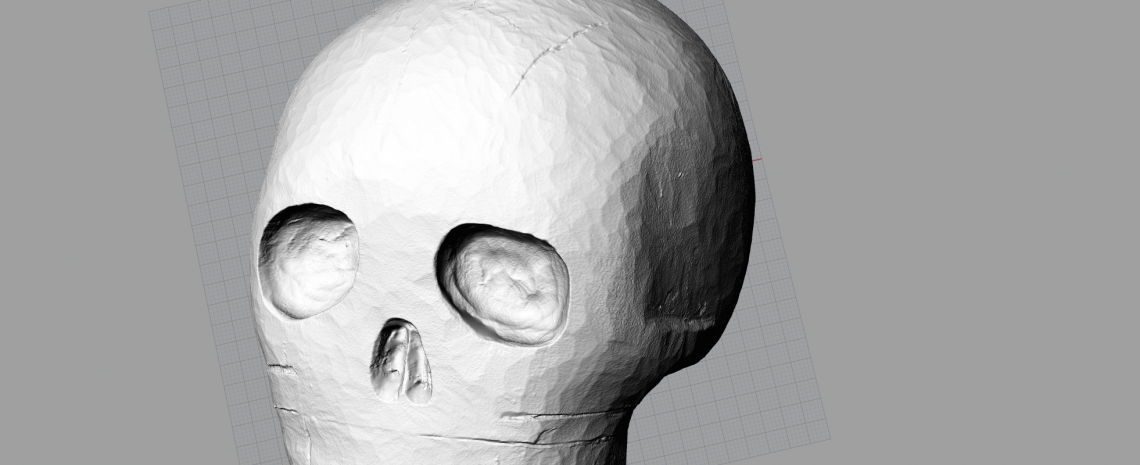

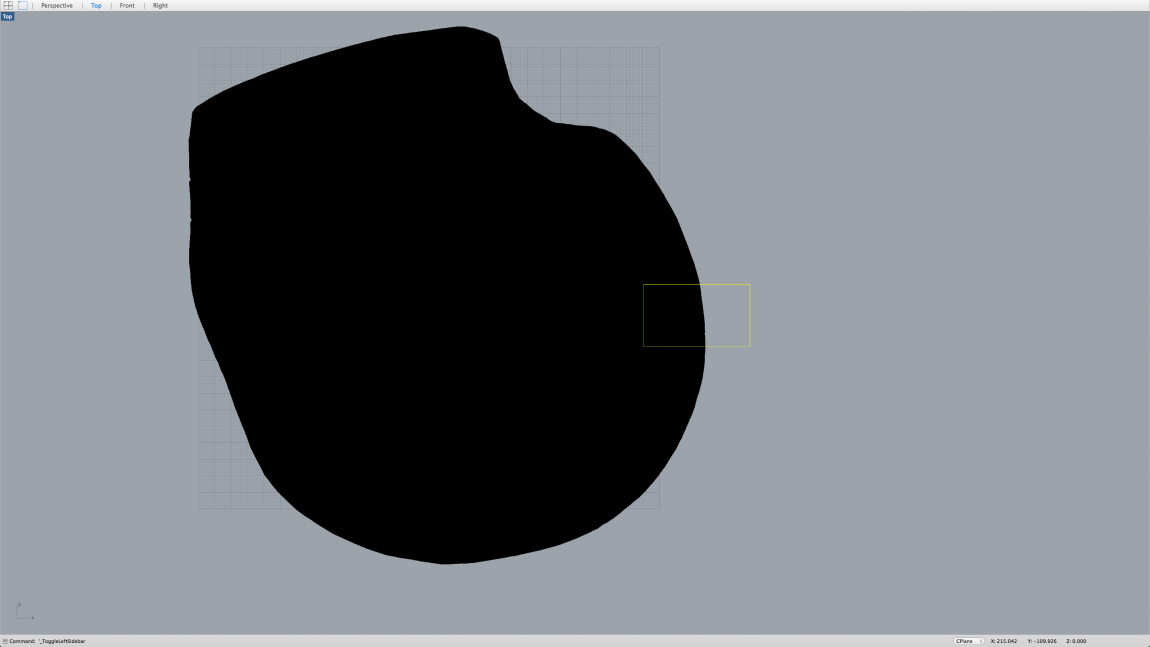

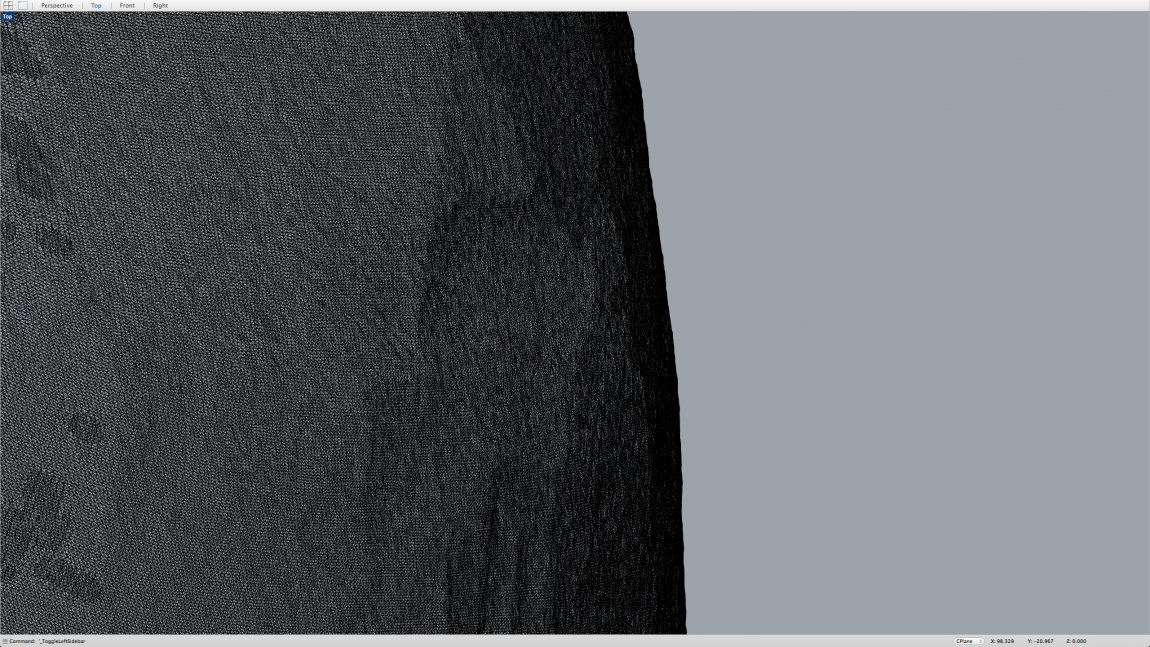

The wireframe model of the scanned skull, as seen in Rhinoceros. The yellow rectangle represents the inset for the closeup view of the polygon detail (see next image).

The inset view of the skull’s wireframe model, as seen in Rhinoceros. The final 3D model contains over 7.74 million polygons.

While we still have a lot to learn to fully utilize the features and capabilities of this scanner, we’ve begun digitizing models for our early wearables kit, starting with the wooden skull carved by Nicole last semester. Below are a few shots of the process of scanning the skull, mandible, and crossbone that will be used to remake Gustave Trouvé’s stickpin.

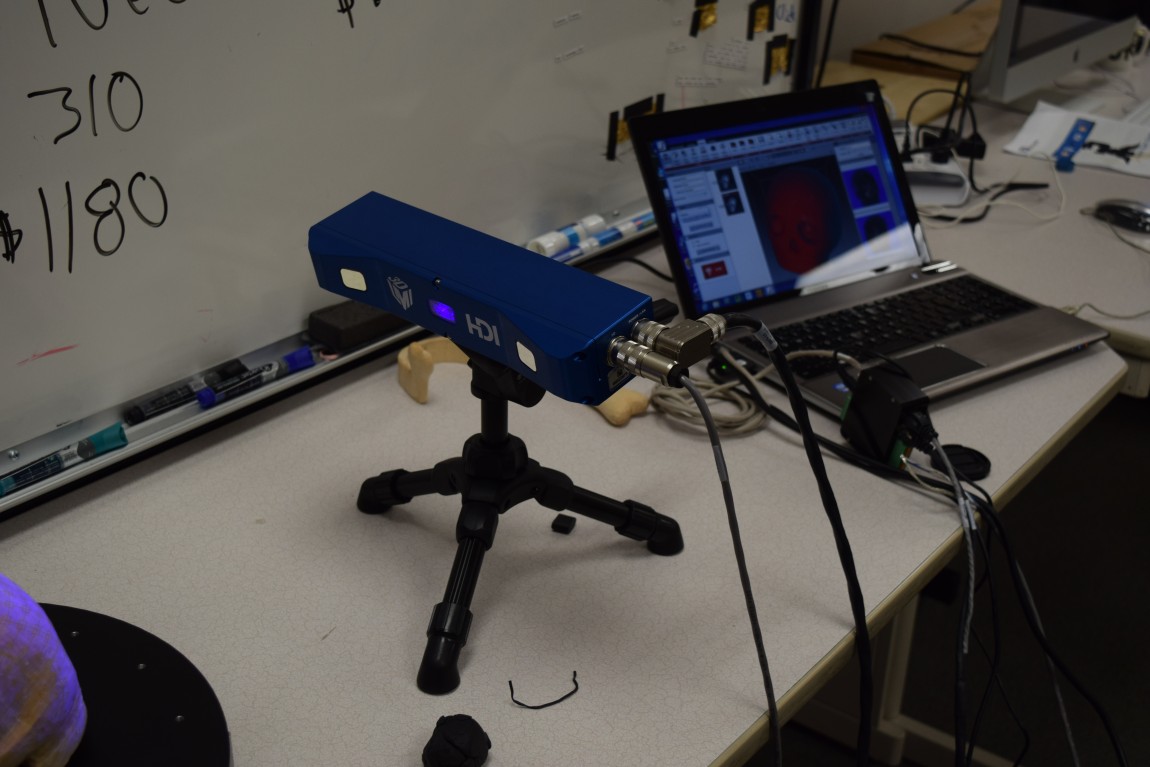

The setup for scanning objects on the turntable. The scanner is in the foreground, connected to a PC workstation.

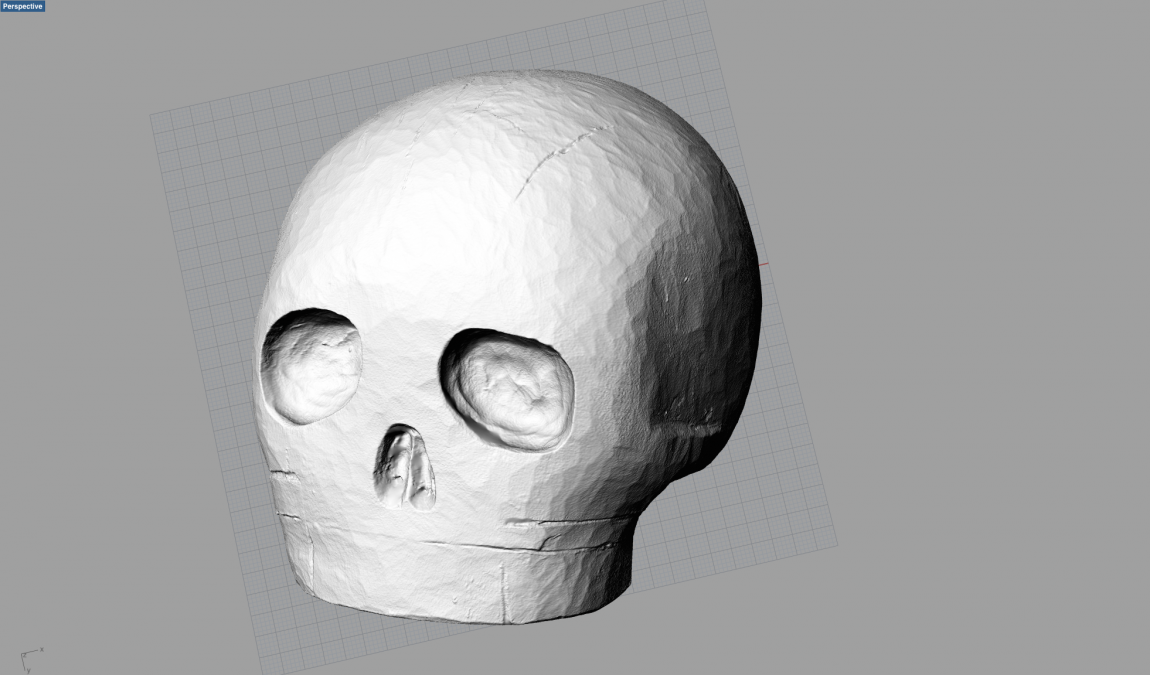

Once the scans were completed, the 3D models were exported as STL and OBJ files. These files will be modified for reproduction on another one of the lab’s new pieces of equipment (a Roland SRM-20 milling machine) in the weeks to come.

The rendered 3D model of the scanned skull, as seen in Rhinoceros. The scanning software used with the HDI 120 is FlexScan3D.

Post by Shaun Macpherson, attached to the KitsForCulture and Makerspace projects, with the physcomp and fabrication tags. Featured images for this post care of Shaun Macpherson.