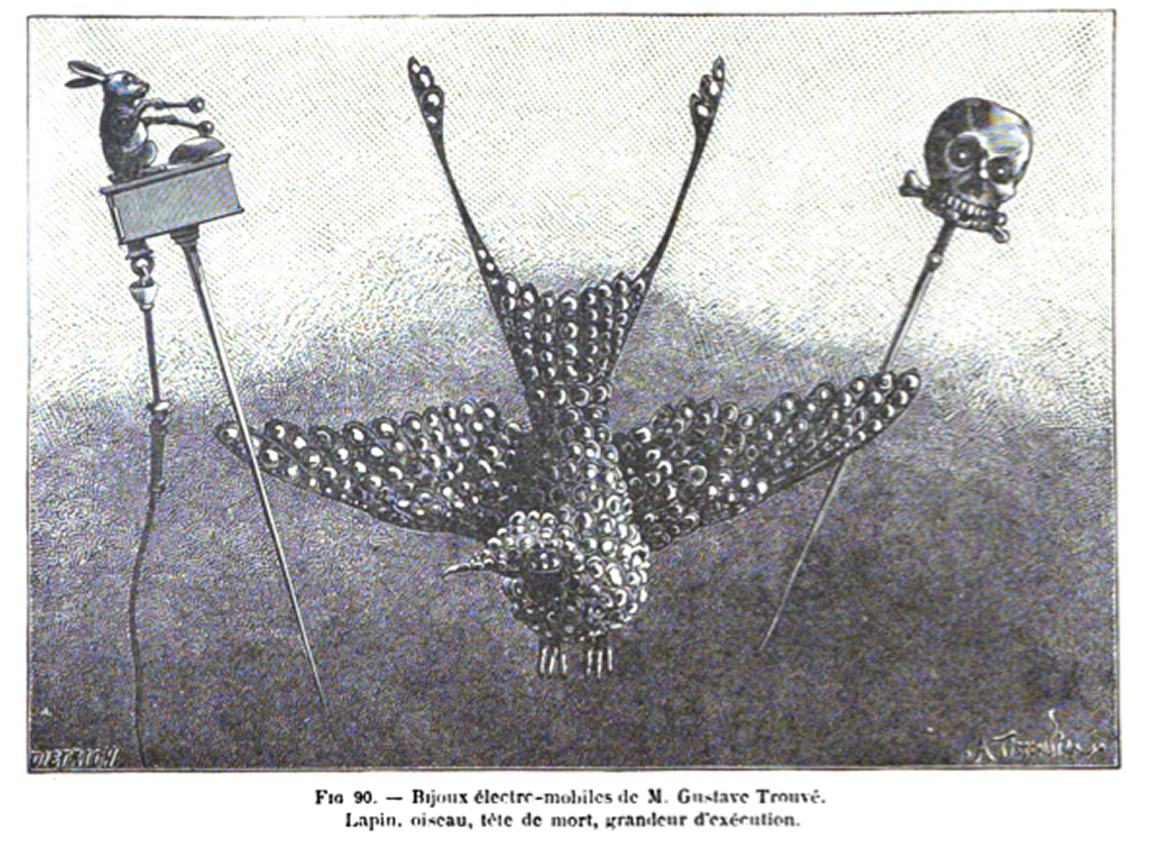

In our continued work on the Kits for Cultural History, the Maker Lab team has been focusing on Gustave Trouvé’s skull stick pin: a Victorian-era, motorized skull that was designed to adhere to a man’s tie, gnash its teeth, and roll its eyes. To make the pin (picture below, from our GitHub repo), Trouvé collaborated with artist, Auguste-Germain Cadet-Picard.

One phase of this kit has been analysing and recreating the skull form itself. While discussing the possible ways to create the skull, the team came up with the idea to carve it from wood and then digitize it. By creating a real world object and scanning it to make a digital model, we will be able to retain a handmade impression, in contrast to a born-digital object that continues to feel digital even after it is printed. With this digitization process in mind, we decided that it would be best to carve the skull in components that could be scanned separately: the upper skull, the jaw, and the crossbones, for instance.

Our first step in the carving process was to establish the main aesthetic characteristics of Trouvé’s skull, as well as other skull jewelry from the Victorian period. By looking into visual depictions of skulls from this era we found the majority were associated with mourning and worn in memory of a loved one or as a memento mori—a reminder of one’s own mortality. From these visual depictions, we discerned the following main characteristics of Victorian skull jewelry relevant to Trouvé’s stick pin: flattened, simplified teeth; elongated cranium; jaw wide and flat (not pointy and narrow); thick connection piece for the jaw; back of the head a bit open; and crossbones in a very round style. Taking these characteristics alongside images of Trouvé’s skull piece, I made some technical drawings to help guide the carving process, with a focus on the first section that I would be carving: the upper skull. Here’s one of the drawings:

For the carving, we chose to work with basswood. It is a hardwood and therefore retains detail well, but it is still soft enough to carve by hand. Also, it is the wood that I have the most experience carving, having worked with it on previous artistic projects. After the wood arrived from the lumberyard, I began preparing it for carving. (Please note: these steps should not be interpreted as instructions. This work was conducted in a supervised space, with training.)

Plane and joint the wood: In this step the wood is brought through two machines, a jointer and then a planer, which remove any warp in the wood, creating a flat, level surface to work with.

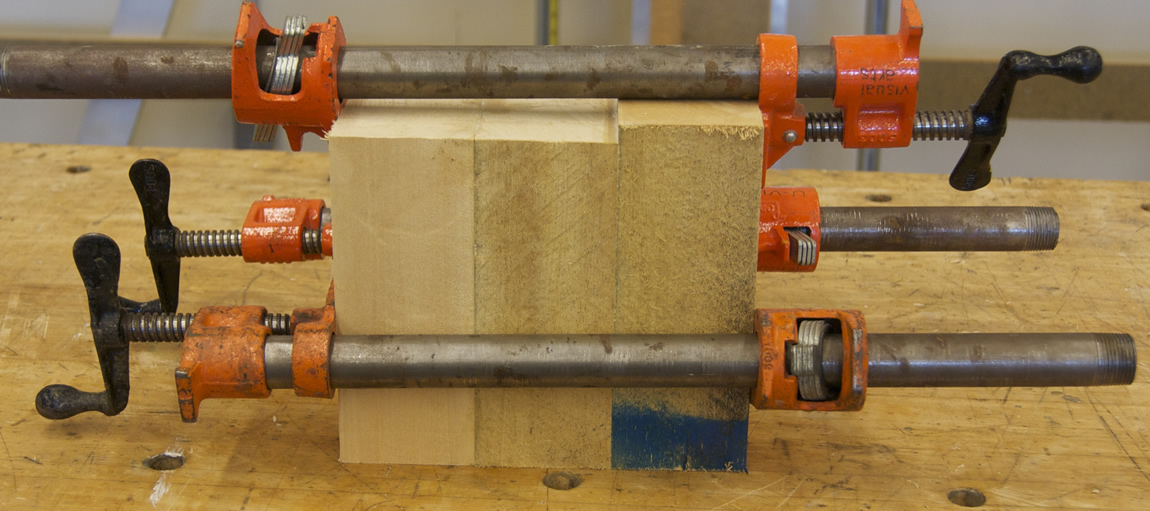

Cut and laminate the wood: I then used a chop saw to cut the wood into lengths that could be laminated (glued) together to create a cube that would be a good working size for the skull.

Cut using the bandsaw: I then used my technical drawings of the skull as a guide to cut a rough form using a bandsaw. This step is incredibly helpful, as the more material that can be removed by mechanical means, the easier it is to hone it by hand.

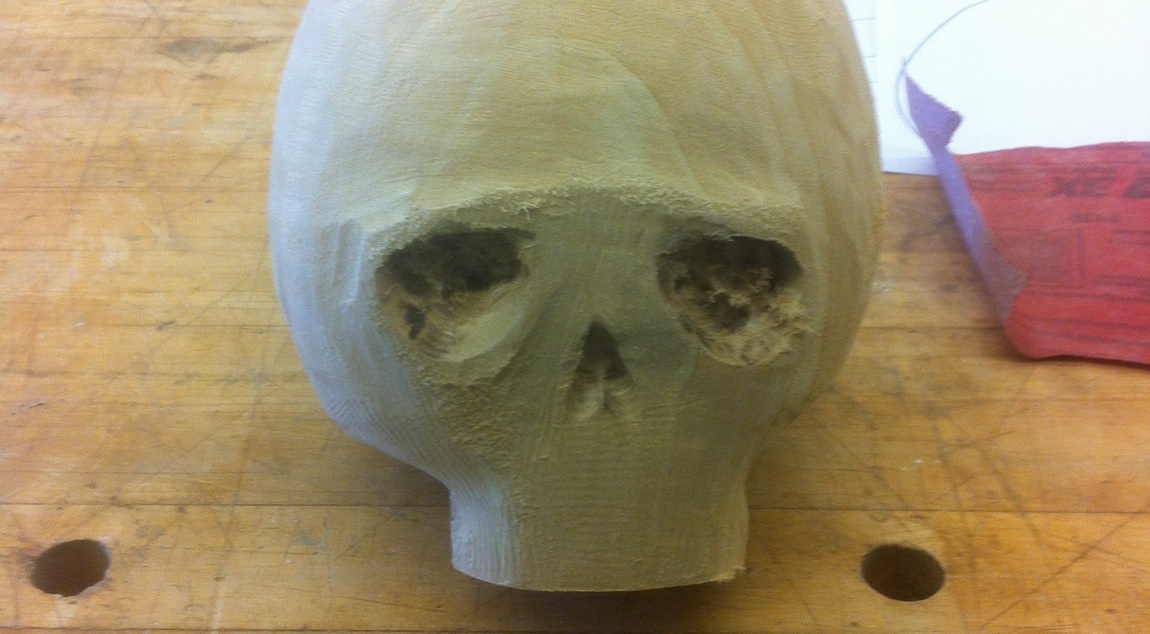

Sculpt using die grinder and sanders: In order to get the wood even closer to the desired form, I sculpted it using a die grinder (with various bits) as well as an orbital sander.

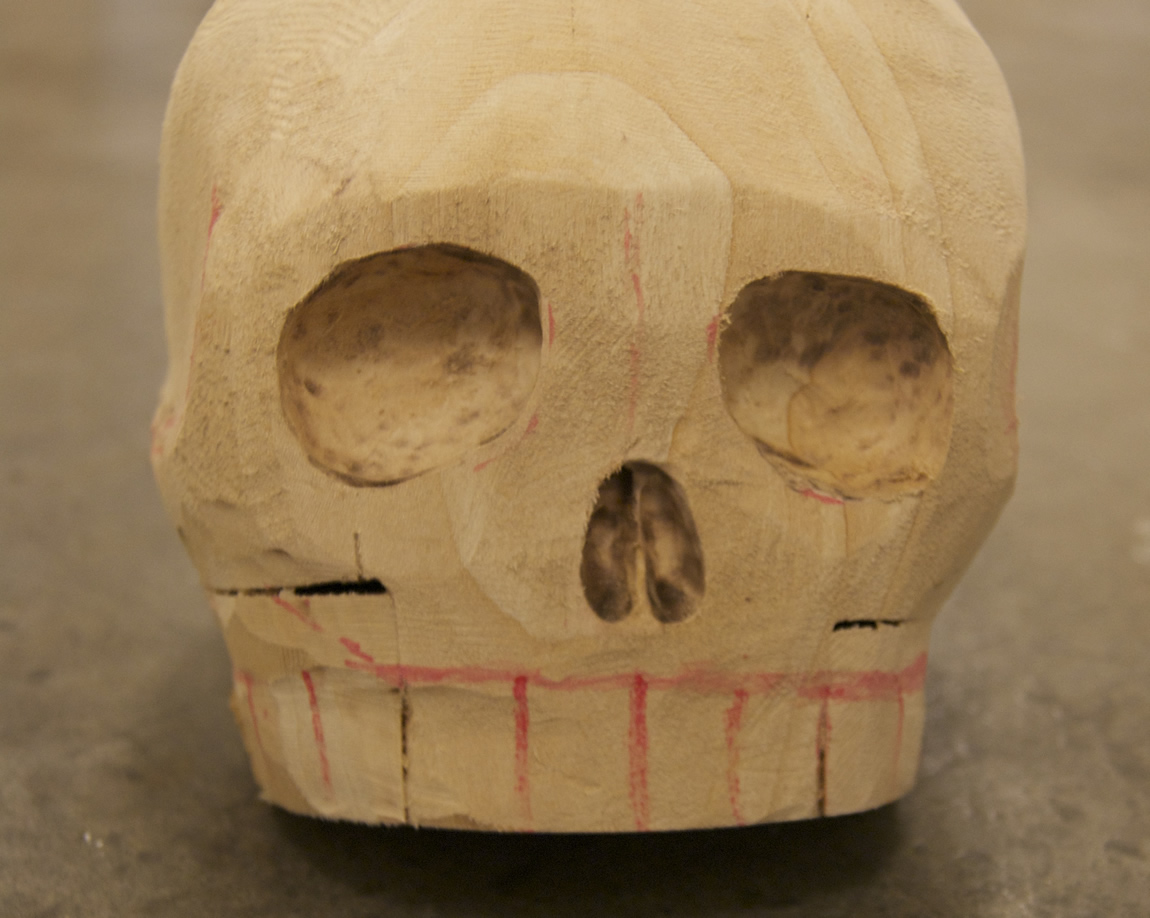

At this point, the Maker Lab team discussed the skull’s development, and we collectively decided on some points of improvement in order to create a higher fidelity to Trouvé’s skull, specifically altering the width of the teeth, the sloping in the temples, and the nose shape of the skull. With these improvements in mind, I laminated two more pieces of wood onto the jaw section in order to widen it. I then sculpted it down again.

Sculpt using hand-carving tools: Now that the skull is as refined as I could get it using power tools, I have started the process of hand-carving using a carving knife and chisels. This allows for much more control as well as creating a nicer finish to the wood as the hand tools slice trough the wood to reveal the grain (in contrast to power tools, which scratch the surface).

At this point I will continue to carve the skull, with feedback from the team, and will go through the same process for the carving of the jaw and the crossbones that are featured in Trouvé’s skull piece. More from me soon.

Post by Nicole Clouston, attached to the KitsForCulture project, with the fabrication tag. All images in this post, except the image from Barral (1891), care of Nicole Clouston.